Capabilities

A team of experts and state-of-the-art equipment, at your service.

Quality Makes Us Global

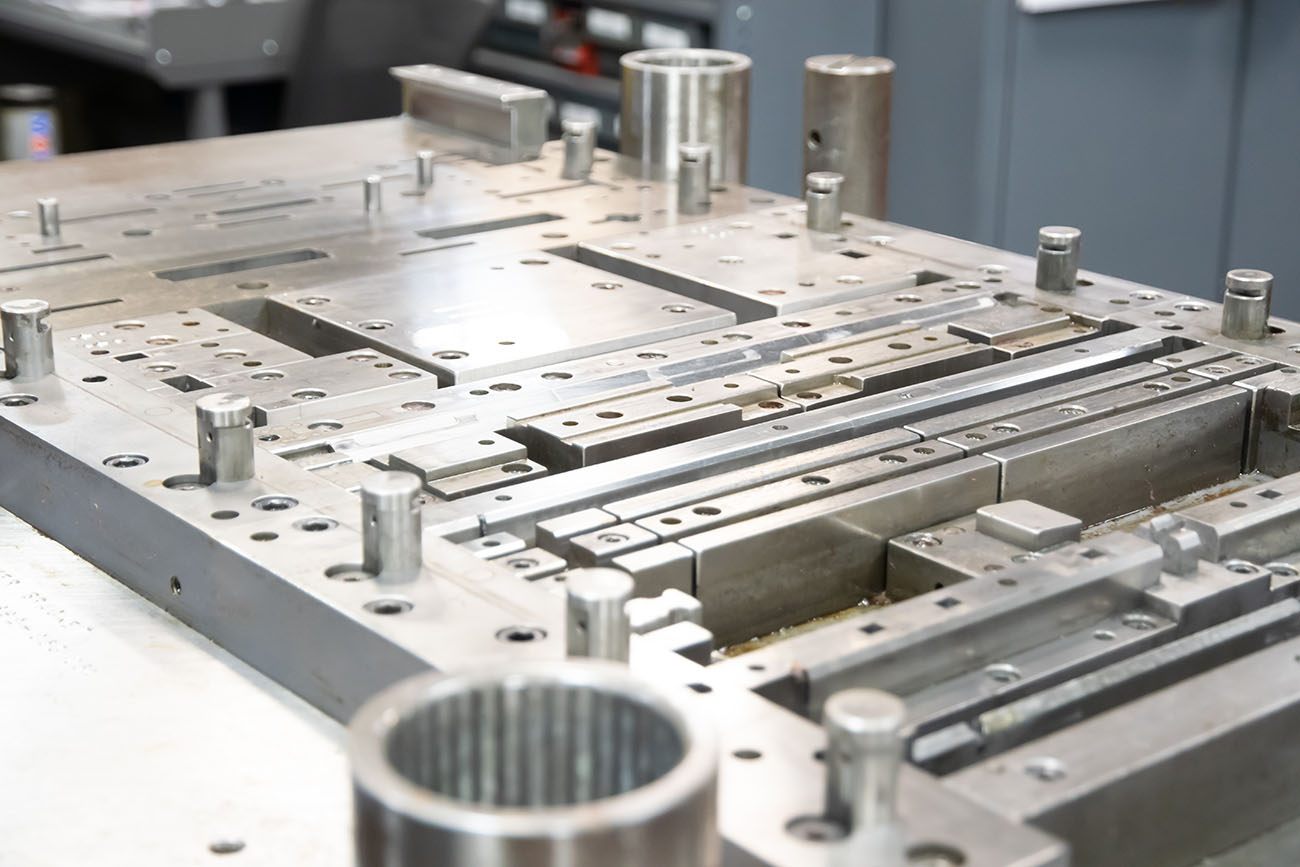

Precision Metal Fabrication with Quality and Efficiency in Mind

With so many ways to shape and form metal into every conceivable part or component, Global Forming provides customers unparalleled experience in a range of specific capabilities well suited to a wide range of projects.

Global Forming has seven roll forming lines for maximum flexibility in converting flat sheet metal strips 1.5–2.5 inches wide (38.1 to 63.5mm), 0.004–1.25 inches (0.1015 to 31.75mm) thick into complex profiles at whatever length is needed. Additional operations can be incorporated into roll forming lines to punch features into the workpiece such as a hole, notch, embossment, or shear.

A large fleet of metal stamping presses at Global Forming ranging in size from 12 tons to 150 tons of pressure and bed sizes ranging all the way up to 48 inches by 84 inches. These machines are flexible and can be adapted to a wide variety of metalworking processes, including

punching, blanking, embossing, coining, bending, flanging, drawing and deep drawing, hemming, progressive die stamping, and transfer die stamping.

This cold-forming metalworking method shapes metal through bending while constant stretching tension is being applied to the workpiece to prevent distortions such as wrinkling and buckling. Now widely used in automotive, aerospace, and many other applications, stretch bending and forming offer a distinctive set of advantages customers appreciate.

Global Forming offers a range of assembly services that save time and money for our customers. Our value-added assembly services are quick, accurate, and efficient, allowing customers to enjoy significant savings in time, tooling, labor, transportation, and warehousing costs, as well as fewer defects and errors

Our expert engineers take a customer-supplied 3D part or component design and put it through a thorough and rigorous design evaluation to determine manufacturability before tooling and production. We’ve built a reputation for short lead-times without sacrificing quality. This is when PPAP and APQP play a major role to ensure all specs are met while at the same time meeting on-time delivery requirements.