Tooling

Quality Makes Us Global

Expert Tooling Through Global Forming

Just about any process used to shape or form metal requires some kind of die to be tooled. This could be roll forming (roller dies), stamping (cutting and forming dies), stretch bending (form die), or welding fixtures, all of which hold a workpiece in place while welding takes place. Global Forming manages the tooling process for your project’s die(s) or fixtures to ensure manufacturability as well as the ongoing care of each die to ensure maximum life cycle and productivity.

Machine Tooling to Match the Manufacturing Process of Your Project

Another consideration is the cutting die that will be used to separate the part from the strip of sheet metal material being used. This cut-off die and press may be positioned on the production line to cut the blank from the sheet metal strip before forming begins or it may be positioned at the end of the line to cut the formed part as the last step of the process.

On the other hand, a pre-forming cutoff die is much simpler since it’s only cutting the flat sheet metal to the right part length. A post-forming cutoff die, by contrast, must be tooled to match the part profile that has been formed, making it a more complex and expensive die to tool. In order to avoid deformation of the final part, all the surfaces of the profile must be supported during cutoff, which may not be feasible. Then again, the cutoff die might also be tooled to incorporate one or more additional operations such as punching or notching, thereby avoiding additional tooling of dies to perform those as separate secondary operations on the pieces. A complex post-forming cutoff die will also present higher maintenance costs over time compared to a precut die.

Precut pieces tend to cause more stress to the roller dies in the production line because each part has a leading edge that stresses the rollers, whereas when the material is a continuous strip, the only leading edge is the one at the very beginning of any given production run. A post-forming cutoff die will likely cause some amount of part deformation such as burrs or rough ends, which will in turn require some post-forming secondary operations to address.

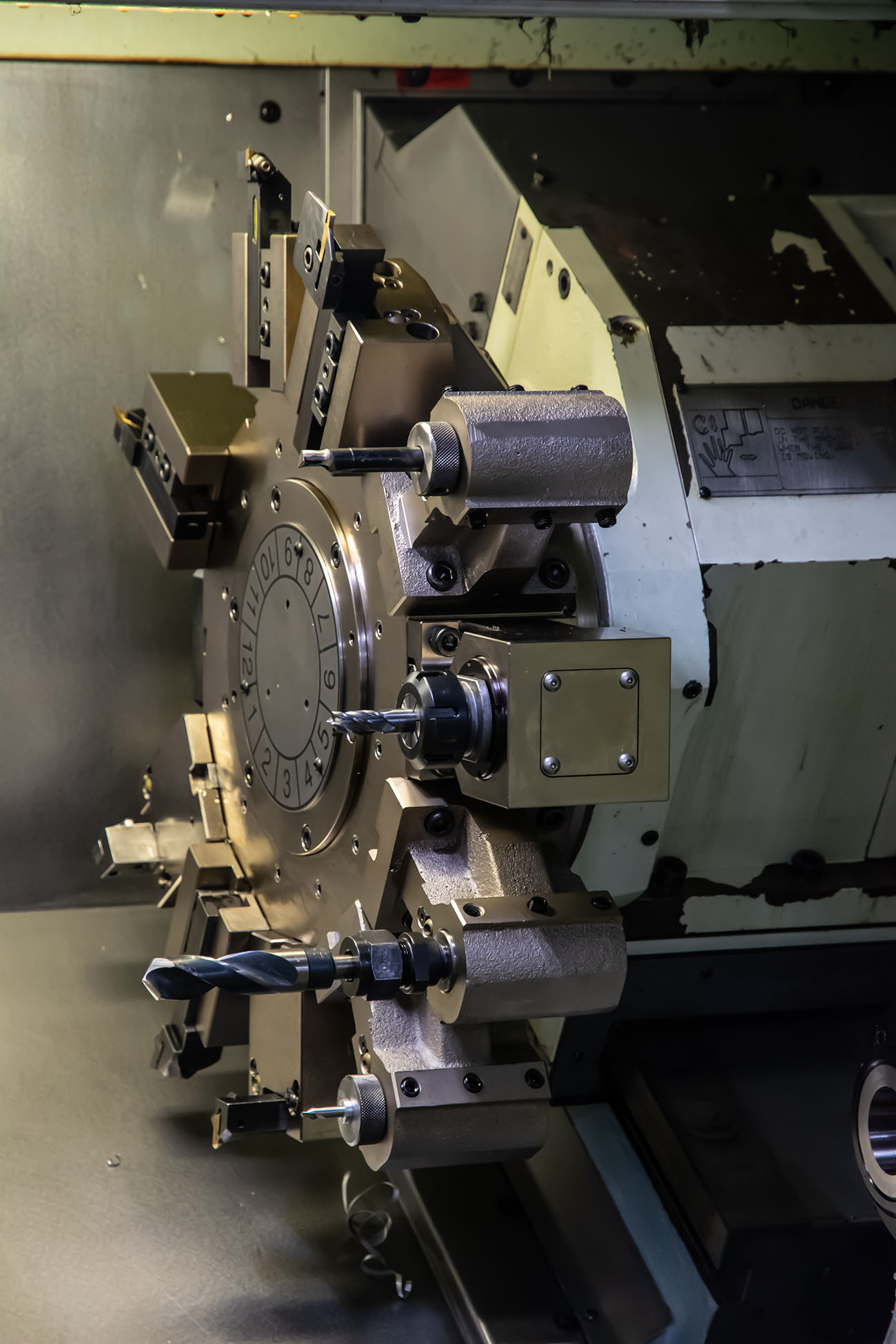

If the final profile of the metal part or component is geometrically complex, the workpiece may need to pass through multiple die stations, which are called progressive dies for progressive stamping and the stock material will be a continuous strip of sheet metal. If the stock material has already been cut into blank workpieces, then the multiple stations are referred to as transfer dies since the workpiece must be mechanically moved from station to station as opposed to the continuous feed of a sheet metal strip in progressive stamping. A combination die is one that performs multiple cutting and forming operations in one stroke of the stamping press.

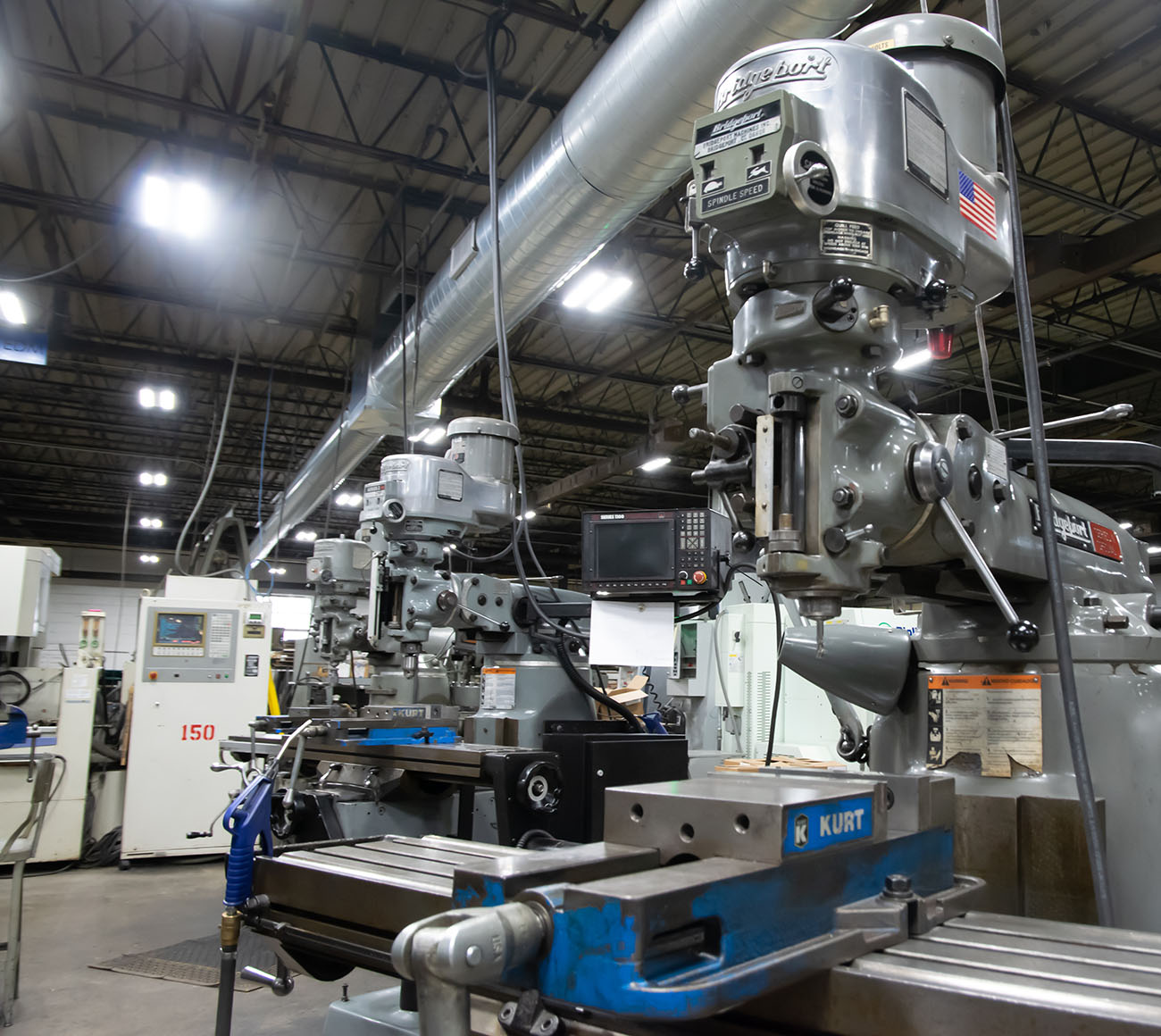

All dies must be carefully designed with advanced CAD software, then evaluated for manufacturability, which may be achieved by tooling experts using computer simulation software. Only after validation of the designs would tooling the dies begin by a method such as CNC machining or Wire EDM.

When a part needs to be welded during the manufacturing process, the part must be held in place by a welding fixture. This sounds simple enough, but in truth is surprisingly complex. It becomes quickly apparent that the quality of the final part relies heavily on a well-designed welding fixture. If the fixture holds the part too tightly, it might end up deformed after being released from the fixture post-welding. Held too loosely, however, and the weld might not be nearly as precise as it needs to be. The fixture also has to be designed in a way that the part can be quickly removed from it post-welding in order to keep pace with the desired production speed. The fixture also must not be in the way of the area the welding gun needs to access to do its job. If your parts have tight tolerances, then welding fixtures require precision machined or ground fixture parts.

Regardless of what kind of dies or fixtures are needed for your project, Global Forming will manage the entire tooling process for you from design validation to the tooling of production dies and fixtures. Get more information by contacting Global Forming through the contact us page of our website, by phone at 317.290.1000, or by email to rfox@globalforming.us to discuss your project and its tooling needs.