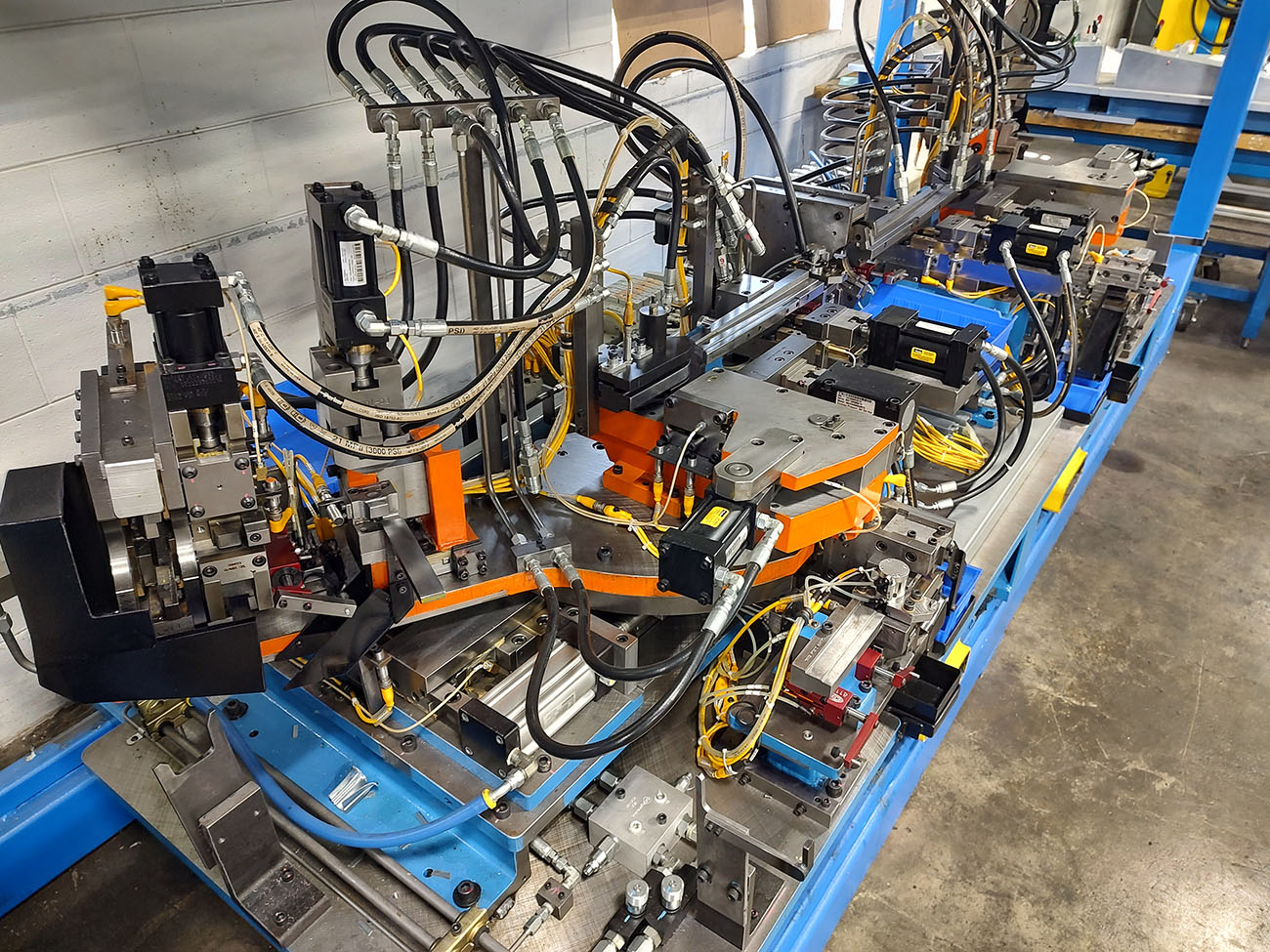

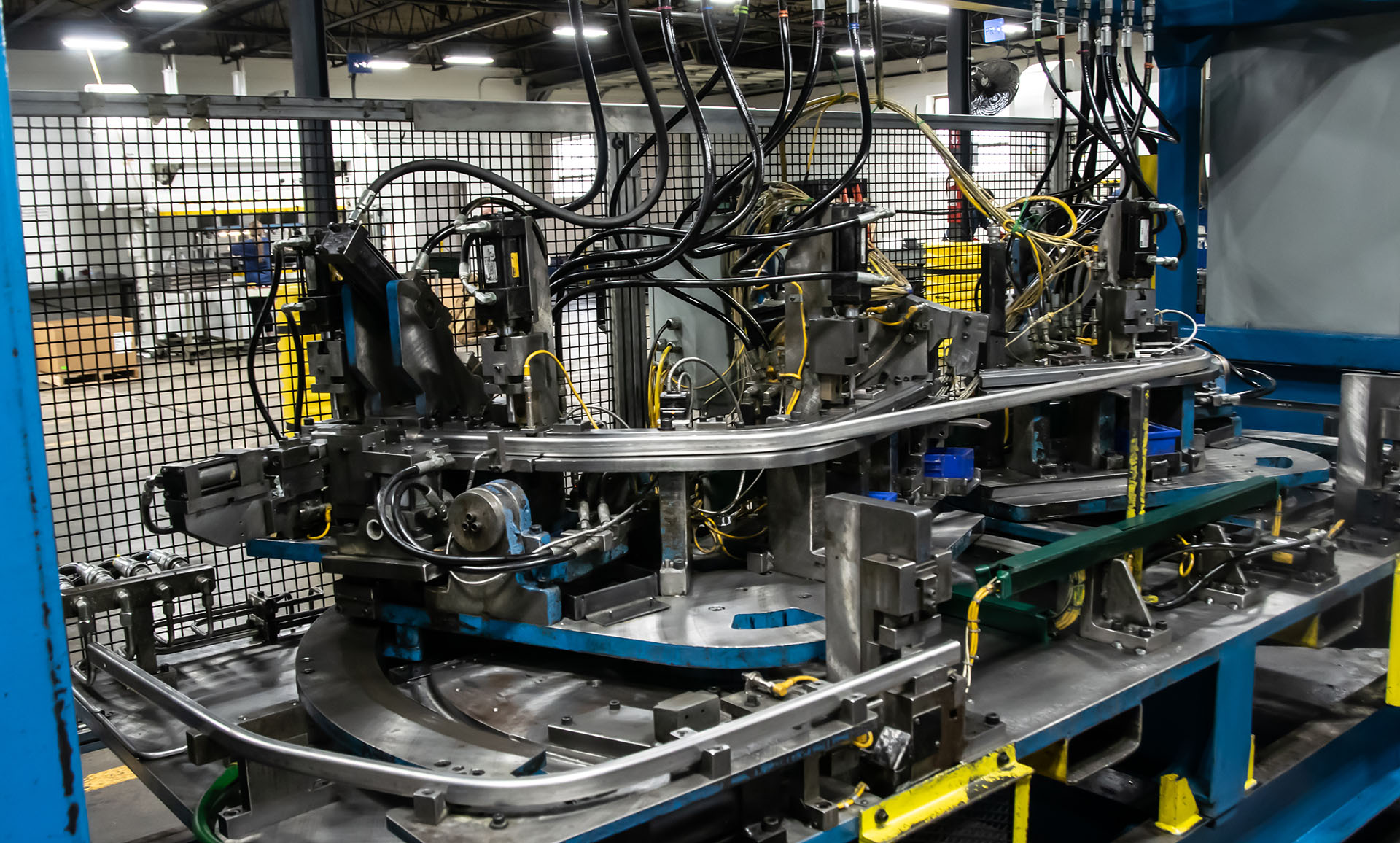

Stretch Bending Metal Forming Process

Quality Makes Us Global

Stretch Bending Metal Shaping at Global Forming

The Rise of Stretch-Bending for Better Results

The workpiece is pressed onto or around a machined form (a die, also called a form block) to achieve a part with one or several different curve radii. In the industry, the machine accomplishing the work may be called a stretch bending machine, stretch press, a stretch former, and so on. The stretching is what compensates for the compression forces on the inner surface of the workpiece and basically pulls out any wrinkles or buckles before they can happen.

Reduced Material Costs

Energy Efficiency

Unparalleled Accuracy

Flexibility

Quality Parts

Stronger Parts

Reduced Spring-back

Low Residual Stresses

Lower Tooling Costs

Process Efficiency

Cost Effective

Is stretch bending or stretch forming the right metal shaping technique for your project? It depends on a lot of different factors. Feel free to contact us and our team of experts will help you determine if Global Forming’s stretch bending capabilities are the right fit for your project.